Speed Control of D.C Motors:

The speed of a d.c. motor is given by:

From exp. (i), it is clear that there are three main methods of controlling the

speed of a d.c. motor, namely:

(i) By varying the flux per pole (f). This is known as flux control method.

(ii) By varying the resistance in the armature circuit. This is known as

armature control method.

(iii) By varying the applied voltage V. This is known as voltage control

method.

Speed Control of D.C Shunt Motors:

The speed of a shunt motor can be changed by

(i) Flux control method

(ii) Armature control method

(iii) Voltage control method

1. Flux control method:

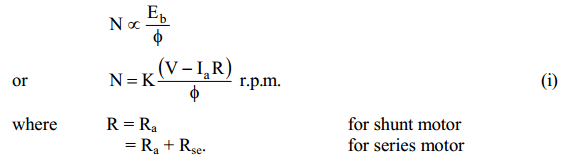

It is based on the fact that by varying the flux f, the motor speed (N µ 1/f) can be changed and hence the name flux control method. In this method, a variable resistance (known as shunt field rheostat) is placed in series with shunt field winding as shown in Fig. (5.1).

The shunt field rheostat reduces the shunt field current Ish and hence the flux f.Therefore, we can only raise the speed of the motor above the normal speed (see fig. 5.2). Generally, this method permits to increase the speed in the ratio 3:1.Wider speed ranges tend to produce instability and poor commutation.

Advantages of flux control method:

(i) This is an easy and convenient method.

(ii) It is an inexpensive method since very little power is wasted in the shunt field rheostat due to a relatively small value of Ish.

(iii) The speed control exercised by this method is independent of the load on the machine.

Disadvantages of flux control method:

(i) Only speeds higher than the normal speed can be obtained since the total field circuit resistance cannot be reduced below Rsh—the shunt field winding resistance.

(ii) There is a limit to the maximum speed obtainable by this method. It is because if the flux is too much weakened, commutation becomes poorer.

Note: The field of a shunt motor in operation should never be opened because its speed will increase to an extremely high value.

2. Armature control method:

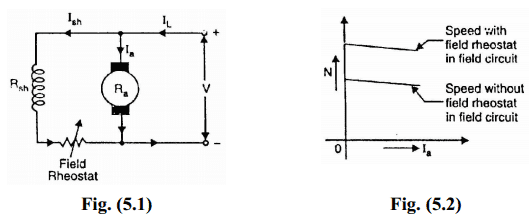

This method is based on the fact that by varying the voltage available across the armature, the back e.m.f and hence the speed of the motor can be changed. This is done by inserting a variable resistance RC (known as controller resistance) in series with the armature as shown in Fig. (5.3).

Due to voltage drop in the controller resistance, the back e.m.f. (Eb) is

decreased. Since N vs Eb, the speed of the motor is reduced. The highest speed obtainable is that corresponding to RC = 0 i.e., normal speed. Hence, Armature control method can only provide speeds below the normal speed (See Fig. 5.4).

Disadvantages of armature control method:

(i) A large amount of power is wasted in the controller resistance since it carries full armature current Ia.

(ii) The speed varies widely with load since the speed depends upon the voltage drop in the controller resistance and hence on the armature current demanded by the load.

(iii) The output and efficiency of the motor are reduced.

(iv) This method results in poor speed regulation.

Due to above disadvantages, armature control method is seldom used to control the speed of shunt motors.

Note: The armature control method is a very common method for the speed

control of d.c. series motors. The disadvantage of poor speed regulation is not important in a series motor which is used only where varying speed service is required.

3. Voltage control method:

In this method, the voltage source supplying the field current is different from that which supplies the armature.This method avoids the disadvantages of poor speed regulation and low efficiency as in armature control method. However, it is quite expensive.Therefore, Voltage control method of speed control is employed for large size motors where efficiency is of great importance.

(i) Multiple voltage control: In this method, the shunt field of the motor is

connected permanently across a fixed voltage source. The armature can be

connected across several different voltages through a suitable switchgear.

In this way, the voltage applied across the armature can be changed. The speed

will be approximately proportional to the voltage applied across the

armature. Intermediate speeds can be obtained by means of a shunt field

regulator.

(ii) Ward-Leonard system:

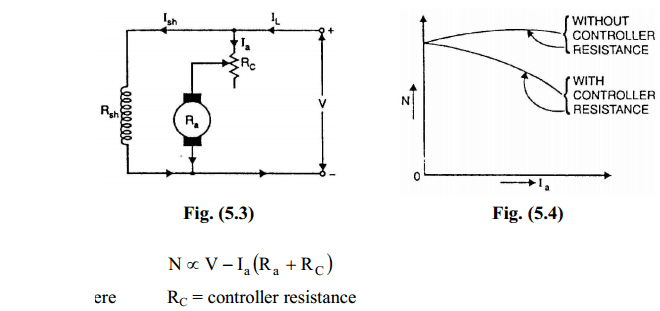

In this Ward-Leonard method, the adjustable voltage for the armature is obtained from an adjustable-voltage generator while the field circuit is supplied from a separate source. This is illustrated in Fig. (5.5).The armature of the shunt motor M (whose speed is to be controlled) is connected directly to a d.c. generator G is driven by a constant-speed a.c. motor A.The field of the shunt motor is supplied from a constant-voltage exciter E. The field of the generator G is also supplied from the exciter E.

The voltage of the generator G can be varied by means of its field regulator. By reversing the field current of generator G by controller FC, the voltage applied to the motor may be reversed. Sometimes, a field regulator is included in the field circuit of shunt motor M for additional speed adjustment. With this method, the motor may be operated at any speed up to its maximum speed.

Advantages of Ward-Leonard system:

(a) The speed of the motor can be adjusted through a wide range without resistance losses which result in high efficiency.

(b) The motor can be brought to a standstill quickly, simply by rapidly reducing the voltage of generator G. When the generator voltage is reduced below the back e.m.f. of the motor, this back e.m.f. sends current through the generator armature, establishing dynamic braking. While this takes place, the generator G operates as a motor driving motor A which returns power to the line.

(c) This method is used for the speed control of large motors when a d.c. supply is not available.

The disadvantage of Ward-Leonard system is that a special motor-generator set is required for each motor and the losses in this set are high if the motor is operating under light loads for long periods.

Speed Control of D.C. Series Motors:

The speed control of d.c. series motors can be obtained by

(i) Flux control method

(ii) Armature Resistance control method.

1. Flux control method:

In this method, the flux produced by the series motor is varied and hence the

speed. The variation of flux can be achieved in the following ways:

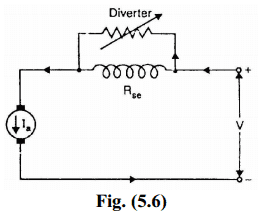

(i) Field diverters:

In this method, a variable resistance (called field diverter) is connected in parallel with series field winding as shown in Fig. (5.6). Its effect is to shunt some portion of the line current from the series field winding, thus weakening the field and increasing the speed (N vs 1/f). The lowest speed obtainable is that corresponding to zero current in the diverter (i.e., diverter is open). Obviously, the lowest speed obtainable is the normal speed of the motor. Consequently, this method can only provide speeds above the normal speed. The series field diverter method is often employed in traction work.

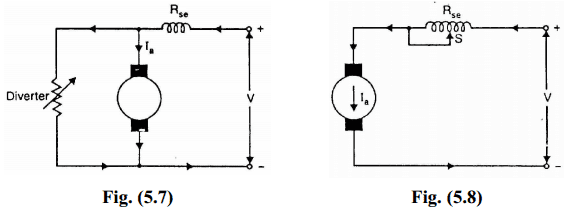

(ii) Armature diverter: In order to obtain speeds below the normal speed, a variable resistance (called armature diverter) is connected in parallel with the armature as shown in Fig. (5.7). The diverter shunts some of the line current, thus reducing the armature current. Now for a given load, if Ia is decreased, the flux f must increase (Q T µ fIa). Since N µ 1/f, the motor speed is decreased. By adjusting the armature diverter, any speed lower than the normal speed can be obtained.

(iii) Tapped field control : In this method, the flux is reduced (and hence speed is increased) by decreasing the number of turns of the series field winding as shown in Fig. (5.8). The switch S can short circuit any part of the field winding, thus decreasing the flux and raising the speed. With full turns of the field winding, the motor runs at normal speed and as the field turns are cut out, speeds higher than normal speed are achieved.

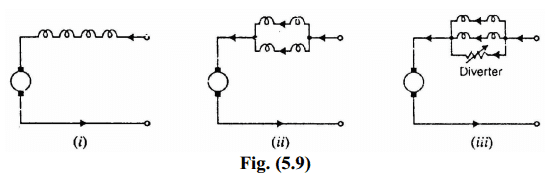

(iv) Paralleling field coils: This method is usually employed in the case of fan

motors. By regrouping the field coils as shown in Fig. below, several fixed speeds can be obtained.

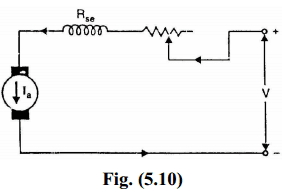

2. Armature-resistance control:

In this method, a variable resistance is directly connected in series with the supply to the complete motor as shown in Fig. (5.10). This reduces the voltage available across the armature and hence the speed falls.By changing the value of variable resistance, any speed below the normal speed can be obtained. This is the most common method employed to control the speed of d.c. series motors.

Although Armature-resistance control method has poor speed regulation, this has no significance for series motors because they are used in varying speed applications.The loss of power in the series resistance for many applications of series motors is not too serious since in these applications,the control is utilized for a large portion of the time for reducing the speed under light-load conditions and is only used intermittently when the motor is carrying full-load.