What is Potentiometer?

Now you are here because you want to know the constructional and working of dc potentiometer.Before going in depth let us understand the working and function of the potentiometer.A potentiometer is an instrument used to measure the potential in a circuit.A potentiometer is an instrument designed to measure an unknown voltage by comparing it with a known voltage.

The known voltage may be supplied by a standard cell or any other known voltage reference source.Measurements using comparison methods are capable of a high degree of accuracy because the result obtained does not depend upon the actual deflection of a pointer, as is the case in deflectional methods, but only upon the accuracy with which the voltage of the reference source is known.

Must Read:

Another advantage of the potentiometers is that since a potentiometer makes use of a balance or null condition, no current flows and hence no power is consumed in the circuit containing the unknown emf when the instrument is balanced.Thus the determination of voltage by a potentiometer is quite independent of the source resistance.

Since a potentiometer measures voltage, it can also be used to determine current simply by measuring the voltage drop produced by the unknown current piling through a known standard resistance.The potentiometer is extensively used for a calibration of voltmeters and ammeters and has, in fact, become the standard for the calibration of these instruments.For the above mentioned advantages, the potentiometer has become very important in the field of electrical measurements and calibration.

Construction of DC Potentiometer:

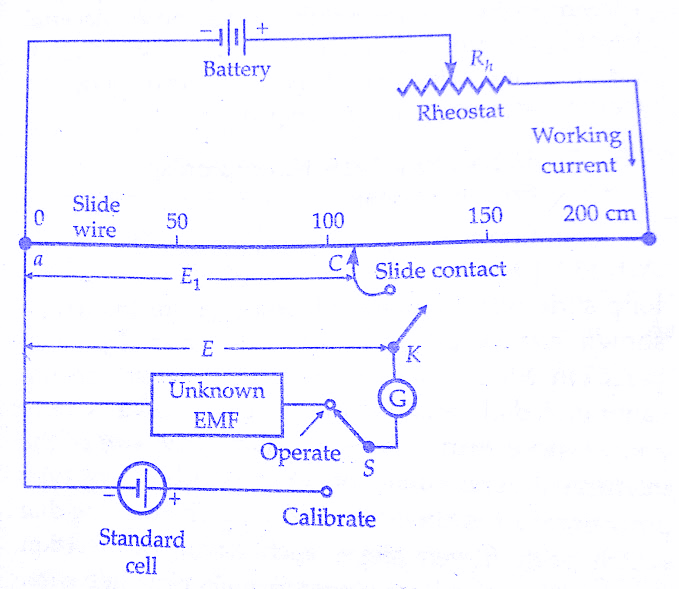

The working principle of potentiometers is based on the figure shown below, which shows the circuit diagram of the basic slide wire potentiometer.

|

| Circuit diagram of basic slide wire Potentiometer |

Working Principle of basic dc Potentiometer:

With switch ‘S‘ in the “operate” position and the galvanometer key K open, the battery supplies the “working current” through the rheostat R and the slide wire.The working current through the slide wire may be varied by changing the rheostat setting.The method of measuring the unknown voltage, E, depends upon finding a position for the sliding contact such the galvanometer shows zero deflection, i.e., indicates a null condition, when the galvanometer key, K. is closed.Let us now discuss the working principle of basic dc potentiometer.

Zero galvanometer deflection or a null means that the unknown voltage, E, is equal to the voltage drop E1, across portion ac of the slide wire. Thus the determination of the value of unknown voltage now becomes a matter of evaluating the voltage drop E1 along the portion ac of the slide wire.The slide wire has a uniform cross-section and hence uniform resistance along its entire length.A calibrated scale in cm and fractions of cm is placed along the slide wire so that the sliding contact can be placed accurately at any desired position along the slide wire.

Since the resistance of slide wire is known accurately, the voltage drop along the slide wire can be controlled by adjusting the value of working current in the basic dc potentiometer.The process of adjusting the working current so as to match the voltage drop across a portion of sliding wire against a standard reference source is known as “Standardisation”.

All the resistors in the potentiometer, with the exception of slide wires, are made of manganin.This is because manganin has a high stability, a low temperature coefficient and has freedom from thermo-electric effects against copper.The slide wire is usually made of platinum-silver alloy and the sliding contact is a copper-gold-silver alloy.

This combination of materials for slide wire and sliding contacts results in a good contact, freedom from thermo-electric EMFs and minimum wear of slide wire.The current controlling rheostat is usually a combination of a stud dial and a multi-turn slide wire.

It is very important that internal thermoelectric EMFs in a potentiometer are minimum.The use of manganin resistors helps in this direction.It is desirable that all the parts work at the same temperature.Therefore, all the parts are covered in a single case.This has the added advantage of protecting the contacts from fumes and dust which may cause corrosion and appearance of voltaic EMFs at the joints.

Potentiometers designed especially for thermocouple measurements have copper terminals.In order to prevent leakage, all the parts must be enclosed, so as to protect them from moisture.The working parts are normally mounted on ebonite or Keramot panels.

Must Read:

Standardisation of the potentiometer:

The procedure for standardisation of the potentiometer is illustrated by the following example :

The slide wire present in above figure has a total length of 200 cm and a resistance of 200 Ω.The emf of the standard cell is 1.0186 V.Switch ‘S’ is thrown to “calibrate” position and the sliding contact is placed at 101.86 cm mark on the slide wire scale.The rheostat Rh is now adjusted so as to vary the working current. This adjustment is carried on till the galvanometer shows no deflection when key ‘K’ is pressed.

Under these conditions, the voltage drop, along the 101.86 cm portion of the slide wire is equal to standard cell voltage of 101.86 V.Since the 101.86 cm portion of the slide wire has a resistance of 101.86 Ω, the working current, in fact, has been adjusted to a value

(1.0186/101.86) x 1000 =10 mA

The voltage at any point along the slide wire is proportional to the length of slide wire.This voltage is obtained by converting the calibrated length into the corresponding voltage, simply by placing the decimal point in the proper position e.g.153.6 cm =1.536 V.If the potentiometer has been calibrated once, its working current is never changed.

Conclusion:

You have learnt Construction & Working Principle of basic DC Potentiometer.

Comment below for any Queries.